CIO Bulletin

“We have built a flexible, agile approach to organize these many moving parts into perfect harmony. inVia revitalizes warehouses, using automation to eliminate stagnation and fuel progress.”

Established in 2015, inVia Robotics emerges as a pioneering technology firm hailing from Southern California. Specializing in cutting-edge robotics warehouse automation solutions, the company spearheads innovation for e-commerce distribution centers and supply chains. Their groundbreaking development, the world's premier "Robots-as-a-Service" autonomous mobile robot picking and goods-to-person system, marks a significant leap forward in warehouse productivity. Unlike traditional automation solutions, inVia's approach ensures seamless integration into existing business operations, fostering enhanced efficiency without disrupting the ecosystem. With a steadfast commitment to advancing warehouse automation, inVia Robotics stands at the forefront of revolutionizing the future of logistics and distribution.

Why inVia Robotics?

Elevate Your Warehouse Efficiency with Intelligent Automation: Unlock unparalleled productivity with inVia's revolutionary Goods-to-Person warehouse automation solution. Their patented technology has been recognized with awards and is designed to boost productivity by up to 5 times.

Streamlined Deployment, Maximized Productivity: Deploy inVia's automation solution within 1-2 months using your existing infrastructure. Enjoy a seamless integration process and start experiencing a significant increase in productivity almost immediately.

Precision and Accuracy at Every Step: With inVia's robotic precision, expect a 99.9% accuracy rate in warehouse operations. Say goodbye to errors and inefficiencies, and hello to a smoother, more streamlined workflow.

Real-world Success Stories: Discover how companies like Gnarlywood have transformed their operations with inVia's automation solution. Benefit from a 65% decrease in labor costs and a remarkable 6x increase in productivity.

Orchestrating Warehouse Workflows with AI: inVia's Warehouse Execution System (WES) software utilizes artificial intelligence to digitize and orchestrate every logistics workflow. Experience intelligent, coordinated movement of resources and goods, leading to reduced operational costs and enhanced customer satisfaction.

Robotics-as-a-Service (RaaS) Subscription Model: Opt for inVia's unique Pay-Per-Productivity subscription model to access all the benefits of warehouse automation without the hefty upfront investment. Pay only for what matters most – your warehouse productivity.

Phased Approach to Warehouse Automation: Choose from a range of options tailored to your business needs, from software-only solutions to fully automated warehouse systems. With inVia's phased approach, you can go at your own pace and adapt to evolving demands seamlessly.

Implementation in Weeks, Not Months: Experience rapid implementation and minimize cycle time and labor costs with inVia's end-to-end fulfillment optimization. Maximize efficiency and stay ahead of the competition with inVia's comprehensive warehouse automation solution.

Transforming Warehouse Fulfillment with inVia PickerWall

Experience unprecedented efficiency in your warehouse operations with inVia PickerWall. This innovative solution revolutionizes the fulfillment process, allowing warehouse workers to work in bursts while robots handle non-stop tasks, 24/7. inVia PickerWall is a dynamic pick/put wall that their robots construct daily based on the day's orders. This system accelerates fulfillment, ensuring your daily service level agreements (SLAs) are consistently met.

With inVia PickerWall's Goods-to-Person automation, achieve pick rates of up to 1000 units per hour (UPH), significantly boosting your replenishment rate and overall productivity. Benefit from a patented workflow that offers a 10x improvement in travel time and distance between picks, optimizing efficiency and reducing fulfillment times.

inVia Picker robots seamlessly deliver inventory to the PickerWall, where warehouse staff are directed on the units to pick and which order containers to sort them into. This eliminates the need for costly warehouse walking and results in a 5x increase in productivity. By decoupling the dependencies between people and robots, inVia PickerWall ensures continuous operation. Robots work non-stop on one side of the wall, while workers operate in bursts on the other side, pulling products and sorting them into order bins. This significantly reduces pick time and accelerates fulfillment rates.

With inVia PickerWall, robots handle mundane tasks, allowing workers to focus on high-order tasks such as decision-making and problem-solving. This intelligent automation enhances overall efficiency and empowers workers to contribute more meaningfully to warehouse operations.

Robotics-as-a-Service: Simplifying Operations for Business Success

In the fast-paced world of business, efficiency and flexibility are key to staying ahead. With Robotics-as-a-Service (RaaS) from inVia Robotics, companies can streamline their operations and focus on core business objectives while leaving the management of robots in expert hands. This subscription-based model minimizes capital expenditures (CapEx) and allows businesses to retain their existing infrastructure, paying only for the productivity they receive.

Pay for Productivity, Not Robots

Traditional approaches to warehouse automation often involve significant upfront investments in purchasing robots and developing expertise to operate them. However, with inVia Robotics' RaaS model, companies can sidestep these challenges. By outsourcing robot ownership, operation, and optimization to inVia, businesses can access the benefits of automation without the financial burden. They pay solely for the productivity delivered by the robots, ensuring a cost-effective solution aligned with their operational needs.

Scale Your Workforce with Ease

One of the key advantages of inVia Robotics' RaaS is the seamless integration of robots into existing workforce structures. While the autonomous mobile robots (AMRs) handle repetitive tasks, expert engineers from inVia remotely monitor and maintain them, effectively extending the company's workforce. This virtual collaboration ensures smooth operations and allows businesses to scale their operations efficiently without worrying about robot management.

Accelerate Return on Investment (ROI)

With inVia Robotics' RaaS model, companies can accelerate their return on investment (ROI) by eliminating the need for significant upfront capital investments. The subscription fee covers all operating costs, including equipment ownership, operation, and maintenance, throughout the service contract's duration. This predictable cost structure enables businesses to allocate resources more effectively and achieve faster ROI on their automation investments.

Effortlessly Handle Demand Spikes

Businesses often face fluctuations in demand, especially during peak seasons or promotional periods. With inVia's adaptable system, companies can effortlessly handle demand spikes without the need for extensive workforce management. Leveraging AI automation, the system can scale to accommodate changes in workload, ensuring seamless operations and consistent productivity levels. This flexibility enables businesses to respond quickly to market dynamics and maintain high levels of customer satisfaction.

Swift Implementation, Seamless Integration

Implementing automation in your warehouse shouldn't be a lengthy, disruptive process. With inVia Robotics' turnkey system, businesses can transition from manual to automated operations in a matter of weeks, not months. This streamlined approach ensures minimal disruption to existing workflows and allows companies to maintain their service level agreements (SLAs) without interruption.

Step 1: Environment Assessment

The journey towards automation begins with an assessment of your current warehouse environment. inVia Robotics experts analyze your workflows and operational data to design the most suitable automation solution tailored to your business needs.

Step 2: Simulation Analysis

Using advanced simulation analysis powered by inVia Logic, their AI automation software, they simulate inventory movements to optimize efficiency. This step ensures that the proposed robotics system aligns perfectly with your operational requirements, including dynamic re-slotting and space allocation.

Step 3: Seamless Integration

Integration is key to a smooth transition to automation. inVia Logic seamlessly integrates with your existing Warehouse Management System (WMS) through APIs and their data translator, inVia Connect. Unlike traditional automation solutions, the system adapts to your warehouse layout and racks, facilitating rapid deployment without the need for extensive modifications.

Step 4: Mapping Your Warehouse

Once integrated, our robots are deployed to map your warehouse layout accurately. Utilizing optimal pick paths, the robots navigate the aisles efficiently, ensuring swift and precise inventory retrieval.

Step 5: Final Optimization and ROI

Before full-scale operation begins, a final optimization ensures that all systems are functioning optimally. With implementation complete, your return on investment (ROI) journey commences, as the efficiency and productivity gains from automation start to materialize.

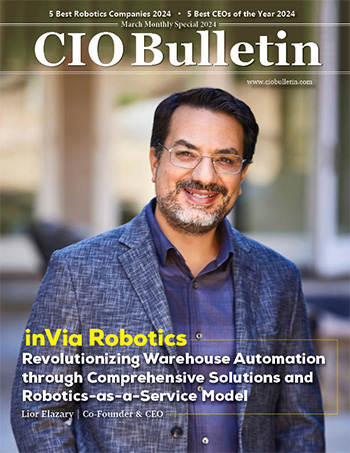

Lior Elazary | Co-founder & Chief Executive Officer

Lior has more than 20 years of experience as an executive in internet networking, robotics, software development and enterprise architecture businesses. He has led and directed diverse teams developing everything from back-office systems to core enterprise technologies. In addition, he has a proven track record of scaling technology companies. He most recently co-founded and later sold EdgeCast, a content delivery platform, with enterprise customers such as Twitter and YouTube.

Lior completed a master’s degree of computer science at the University of Southern California (USC) with a specialty focus on artificial intelligence.He attended a Ph.D. program in robotics at USC where he met his inVia co-founders. Their work together sparked a passion for the dramatic effect robots can have in driving efficiency and productivity, and most importantly in helping people live happier and more fulfilling lives.

Insurance and capital markets